5 Simple Statements About forklift lights safety Explained

5 Simple Statements About forklift lights safety Explained

Blog Article

Mechanical malfunctions are a frequent reason for forklift mishaps and private accidents. Challenges like leaky valves and hoses, worn-out or damaged tires, and defective brakes can induce incidents.

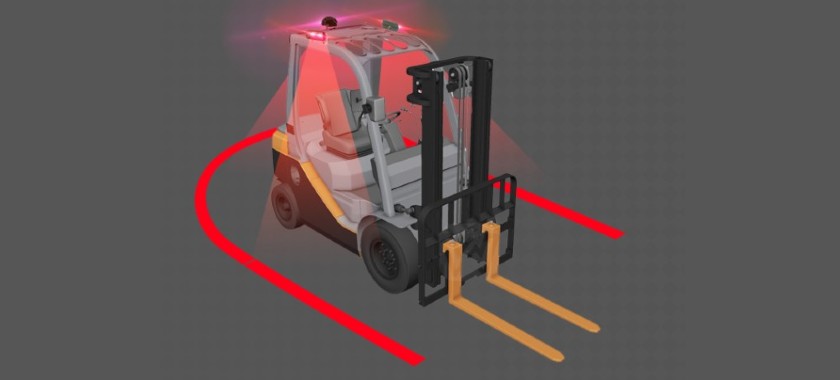

Crimson zone safety lights venture a red “no-go” space across the forklift. The illuminated spot Plainly exhibits the Threat zone for pedestrians, whether the forklift is stopped or in motion.

The Purple Zone lights have been made for any forklift employed mostly indoors. They can be applied on any sort of forklift like sit downs, stand ups, tuggers and a lot more. If you can be making use of them on guy up forklifts, like buy pickers and turret vehicles, purchase one established to try initially ahead of ordering for your fleet to be certain they may work at your heights and in the distinct application.

SharpEagle, a leader in safety merchandise innovation, features a diverse array of safety lights. Make contact with our qualified team right now for aggressive pricing offers, and reap the benefits of our complete companies such as the set up and routine maintenance of forklift safety lights.

The lights alert pedestrians, close by workers, and other forklift motorists from the way and pace of one's forklift solution. The sunshine shines on the ground in entrance, powering, and the perimeters of your forklift.

Our goal is to help neighborhood organizations be as productive and Harmless as is possible. That’s why we offer totally free facility audits. Ensure your operation is OSHA-compliant and as safe as is possible. Speak to a forklift safety specialist online, by cell phone at (800) 226-2345, or in particular person at considered one of our nine areas.

But This could be carried out only if the truck’s other lights are Functioning as meant. Quite a few forklifts now have strobe and also other warning lights as typical options. These kinds of forklift safety lights may also be acquired as incorporate-ons.

OSHA does not mandate blue safety lights, Nevertheless they serve as a great precautionary evaluate to safeguard employees from possible accidents that will happen in small-gentle situations.

Make use of a tape way to indicate the selected path for navigation through the facility. To stop confusion, take into account blocking off locations that forklift operators must not entry.

Comparable to the forklift arc light, the forklift blue Highlight serves the goal of developing a visible warning zone across the forklift. It emits blue mild, outlining the forklift’s perimeter and signalling its existence to Some others.

We could forklift lights safety design and style a tailor made Remedy for your needs and budget. Such as, some functions want their forklift lights wired up And so the lights only run once the forklift is in movement. No challenge, among our professional forklift forklift lights safety experts can wire it up to suit your needs.

40% of all forklift incidents contain a pedestrian. Assure pedestrians keep a secure distance far from the forklift Using forklift lights safety the Red Zone Warning Light-weight. The Pink Zone places a brilliant pink line on the floor, near the forklift, to point out pedestrians in which they are not authorized. This zone can be called the HALO zone and might be adjusted forklift lights safety to the space of the alternative. The Crimson Zone helps protect against foot injuries and collisions from rear close swing, and also, showing the NO GO ZONE all over any piece of cell tools. How is the Red Zone mounted, wired up and modified? The Red Zone lights are mounted to the perimeters of the forklift and can even be mounted around the rear and/or entrance. One Purple Zone light-weight is needed for all sides from the forklift you forklift lights safety need to protect. They feature a Instrument no cost bracket to be able to quickly and easily mount them into the forklift’s overhead guard with no modifying or damaging it in any way. Our Pink Zone online video exhibits the whole mounting procedure. These are mounted somewhat in back again of where the operator sits so as never to interfere with their development as they get on and from the forklift.

Compliance with OSHA rules is fundamental for retaining a safe and healthy get the job done surroundings for staff and forklift operators. OSHA defines particular rules and expectations to protect staff and prevent mishaps.

A halo zone refers to a scheduled region close to a forklift that is certainly marked by a visible indicator, like a painted line or striping.